Checks before installation

- Before installing wooden flooring, control that the room is in correct condition, that the windows are closed, and that all paintwork is dry. Air temperature must not be less than 18°C (ideal temperature 18/22°C), and the relative humidity level must be between 45% and 60%. We recommend these temperatures and humidity levels be maintained permanently after the floor has been laid to guarantee that the flooring remains in perfect condition over time.

- Control that the cement screed sub-floor is as level as possible (the maximum acceptable tolerance is 5 mm over a 2-metre span, measured using a rigid rule). The moisture content of the cement screed must not exceed 2% in weight. When installing flooring over other types of sub-floor (old wooden floors, ceramic tiles, etc) please contact our company for further advice.

- When installing flooring over underfloor heating, control that this type of wooden flooring is suitable for underfloor heating systems (see product data sheet). Also check that the minimum cement screed curing and maturing time has been respected and control that the cement screed heating has been performed correctly. Gradual start-up of the heating system is used to stabilise the cement screed as it will eliminate any possible tension and will bring it to the required dryness level according to the climatic conditions in the room where the flooring is to be laid; this will prevent releasing moisture into the wooden flooring. Before floor installing it is important to control that a vapour barrier is created between the levelling and insulation layers. Check that the minimum thickness of the cement screed is 6 cm, and that the thickness over the heating pipes is at least 3 cm. The minimum curing/maturing times for various types of cement screed must be respected before starting up the heating system:

– 21 days for cement screeds

– 7 days for anhydrite screeds

– 3-4 days for rapid-drying screeds (always follow the manufacturer’s instructions). Once the heating system has been switched on, increase the fluid temperature by about 10°C each day until a temperature of 50°C has been reached; maintain the maximum circulating fluid temperature for at least 10 consecutive days and ventilate the rooms adequately. After this period, gradually cool the fluid temperature by 10°C per day down to 20°C. Switch off the heating 5 days prior to floor installing. In any case, before starting to lay floor boards, control that the surface temperature of the screed is approximately 15/20°C and that the relative humidity level in the room is 45/60%. To avoid possible wooden flooring shrinkage caused by drying out, it is advisable to maintain the underfloor heated slab below a temperature of 26-27°C and the relative air humidity levels between 45% and 60%. This is to ensure an adequate balance in wood moisture content (relative information and data sheets are available on our web site).

- Carefully control that the selected flooring type is suitable for the environment before beginning any installing operations (moisture level, processing, and finish).

G&G Flooring will not accept any claims concerning products after floor laying has been started.

Generic instructions for installation

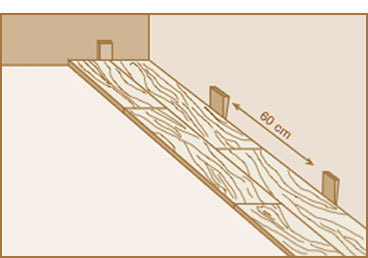

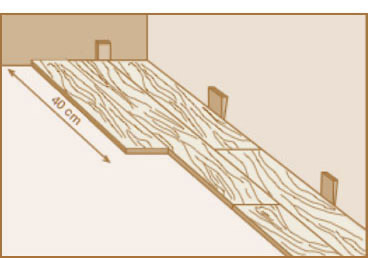

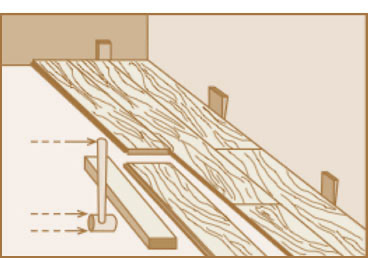

To prevent strong contrasts in wood colour, mix boards from different packs before beginning any installing operations. Begin installing by placing the groove side facing the wall. When installing, leave an expansion gap of about 1 cm from the wall for rooms approximately 4 x 4 metres in size. For larger rooms increase the space around the perimeter by about 1 cm for every additional metre. Always insert spacer wedges to maintain the boards at the correct distance from the walls, and remember to remove them after 12 hours.

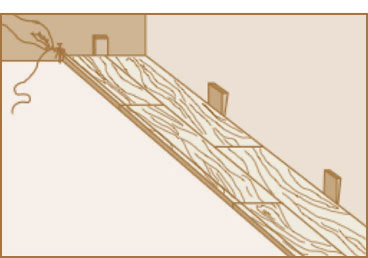

It is advisable to use dilatation joints in rooms over 10 metres in width, where boards are laid in a perpendicular direction. Also maintain the 1 cm space around columns or any other elements protruding from concrete slab. Take great care to lay the first course of boards in a perfectly straight line (it is a good idea to use a chalk line or cord as a guide).

If necessary, insert the boards by tapping with a mallet on the tongue side, protecting it with a striking block about 40/50 cm in length.

When installing, stagger the boards at distances of at least 20/30% of the total board length for each course.

Take great care not to hammer the surface of the board. Be careful not to soil the flooring surface with adhesive: if this should occur, remove the adhesive with a specific product before it dries.

Any scrubbing or scraping action to remove adhesive can cause serious damage to the floor surface. This will create very critical problems in repairing the surface because of the special characteristics of this type of flooring. In any case, please contact G&G Flooring before attempting any type of intervention. When installing a floating floor, control that the product is suitable for this type of application (read the relative product data sheet). Floating floors are laid over a moisture shield (or barrier if necessary) and a sound insulation sheet composed of a foam underlay which is available in various types and thicknesses. The moisture barrier sheeting should be folded to continue vertically against the wall and hidden behind the skirting board.

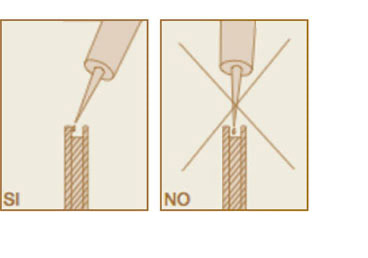

The boards are glued to one another by applying a thin layer of vinyl glue on the top edge of the groove side.

To additional types of installation please contact our office.

A_LUNGO

A-lungo is a waxy resin micro-emulsion, modified oils and natural waxes, ideal for increasing the protection to parquet, (against substances of various kinds) to be used after the basic treatment with oils, it gives a semi-glossy appearance. A-lungo ensures quick and easy application on previously treated parquet. It gives greater protection to the wood together with a soft and pearly appearance, simplifying cleaning and maintenance operations. AVAILABLE VERSIONS: glossy and opaque. IMPORTANT: for regular cleaning, do not use alcohols, or acid, solvent or ammonia baseddetergents.

IT IS IMPORTANT TO FOLLOW THE INSTRUCTIONS INDICATED IN THE PACKAGE.

A_FONDO

A-FONDO is the result of careful research: created on a special high-concentration formula, using raw materials of vegetable origin and ECOCERT and RSPO certified surfactants (main sustainability standard in the sector worldwide), it is ideal for cleansing and maintenance of various surfaces. Thanks to its special formula, in addition to a sanitizing and brightening action, it prevents the formation of mold, bacteria, pathogenic germs. Available in “Mint-Pine” and “Lemon” scents. A-FONDO has the advantage of removing surface dirt on a wide range of floors and / or walls. Thanks to its delicate but incisive cleaning action, it is also suitable for delicate surfaces, such as: stones, marble (including polished), wood, terracotta, porcelain stoneware, ceramics, laminates, glass, linoleum, etc.

IT IS IMPORTANT TO FOLLOW THE INSTRUCTIONS INDICATED IN THE PACKAGE.

SOLIDWAX

SOLIDWAX is a wax for the maintenance of all wooden Lacquered surfaces. It is low in solvents and free from harmful substances for the user and the environment thanks to waxes in water emulsion contained inside theformula. It lends brightness and colour to the floor, delaying its degradation. AVAILABLE VERSIONS: glossy effect (SolidWax Classic) and matt effect (SolidWax Matt).

AVAILABLE VERSIONS: glossy effect (SolidWax Classic) and matt effect (SolidWax Matt).

IT IS IMPORTANT TO FOLLOW THE INSTRUCTIONS INDICATED IN THE PACKAGE.

S-BOND FLEX

S-Bond Flex is a ready-to-use, single-component SiMP (Silyl Modified Polymer) adhesive with

High elastic resistance for wooden floors. S-Bond Flex provides protection against rising damp, ensuring low vapour permeability and sound insulation. The product does not contain isocyanates, is solvent and water free, and has very low emissions according to the EMICODE EC1 PLUS protocol.

CERTIFIED ACCORDING TO: EMICODE EC 1PLUS emissions protocol

EUROFINS IAC GOLD Protocol A+ Emissions Protocol. COMPLIES WITH: EN 14293 Adhesives

for bonding wooden flooring LEED iEQc 4.1; SCAQMD Rule 1168; BAAQMD

Reg 8 Rule 51 CARB VOC emissions regulation ISO 16283.

IMPORTANT: FOLLOW THE INSTRUCTIONS FOR USE GIVEN IN THE PRODUCT DATA SHEET.

U-BOND SPECIAL X-TREME

U-Bond Special Xtreme is a ready-to-use, one-component, hard-elastic wood-flooring polyurethane adhesive

for the professional installation of all wood-flooring. Its hardness and high bonding strength ensure total plank bonding. Thanks to the special formulation and the strong product characteristics, U-Bond Special Xtreme remains a versatile adhesive which allows excellent laying results even in difficult conditions. The product is solvent- and water-free and has very low emission.

CONFORM TO: EN 14293 Adhesives for bonding parquet subfloor LEED iEQc 4.1 ; SCAQMD Rule 1168 ; BAAQMD Reg 8 Rule 51 CARB VOC levels regulation.

IT IS IMPORTANT TO FOLLOW THE INSTRUCTIONS INDICATED IN THE PRODUCT SHEET

B3

B3 is a certified, organic and environmentally compatible adhesive. It is suitable for tongue and groove slats for floating parquet, laminate flooring and ideal in the Green Building sector. It is a single-component, water-based adhesive with only a minor percentage of solvents and very low emissions of volatile organic substances. It is environmentally compatible and safe to use. The B3 adhesive is suitable for bonding tongue and groove-type flooring in floating parquet and pre-finished parquet flooring, planks, laminate flooring, chipboard or plywood panels, and is highly resistant to water.

IT IS IMPORTANT TO FOLLOW THE INSTRUCTIONS INDICATED IN THE PRODUCT SHEET

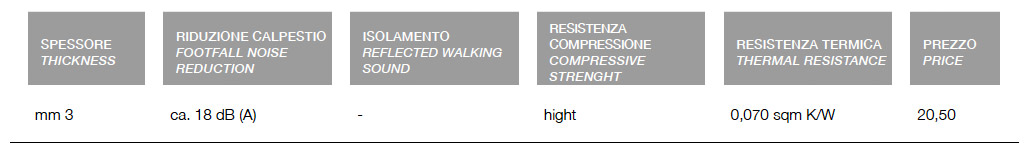

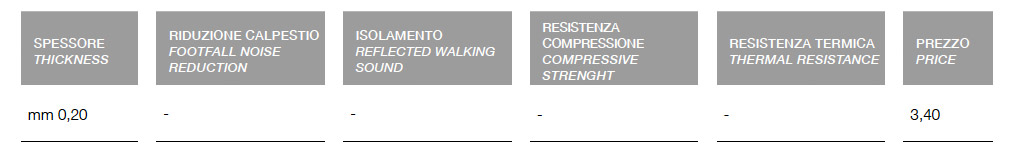

The underlay of parquet represent the important role of creating a soundproof Layers. In this regard, a basic distinction should be made between isolation against the “noise of trampling” (that is heard in the floor below) and the “noise of walking” (that is heard in the same room in which the parquet is fitted). Another important factor to define the quality and durability of the underlay is its resistance to compression, above all in rooms subject to heavy traffic. There are also special Layerss of padding available, which have a vapour barrier: these are necessary in cases of humidity in the sub-flooring.

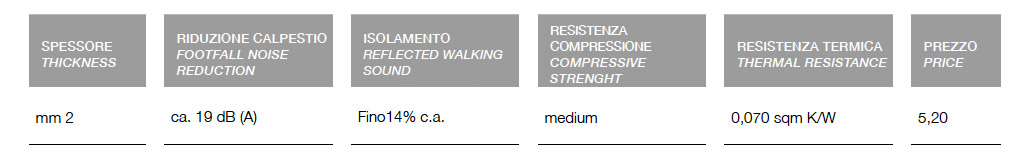

Comfort

Acoustic underlay made from extruded polystyrene. The dense structure compensates floor imperfections, absorbs walking noise and reduces footfall sound. Hight load resistance that improves the durabilityof the floor.

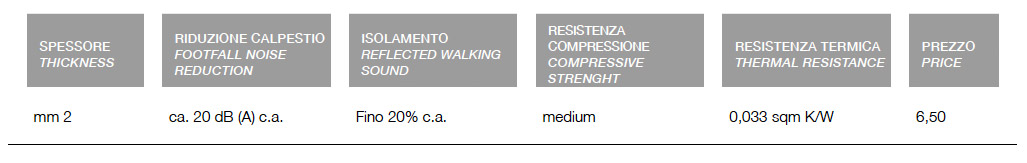

Thermo

Thermo-acoustic underlay in polyethylene foam, ensures good quality reductive impact sound and is very easy to install.

Suitable for installation on heated floors

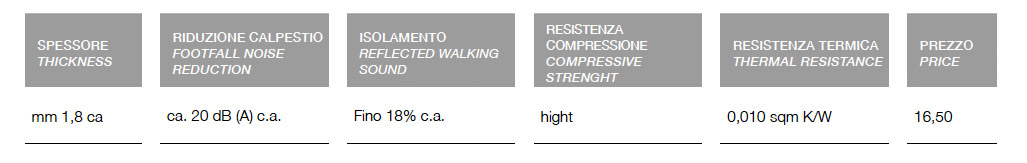

Thermo Plus

Insulation underlay thermally conductive viscoelastic material of high density, specific for the laying of parquet and laminated on radiant floors. The product is coated with an aluminum foil to protect from rising moisture. Class reaction to fire Bfl S1.

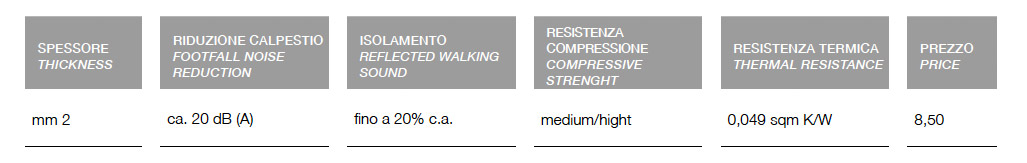

Idro

PE foam, elastic over time, integrated vapor barrier polyethylene, overlapping edge and self-adhesive strips. Moisture resistant and tear resistant, it meets the highest standards with regard to the installation, the resistance and the reduction of impact noise.

Sughero

Underlay made of cork rolls, highly elastic, free from toxic substances and anti-static, exceptional compressive strength, thermal insulation and impact noise reducer.

Nylon

High density polyethylene film with vapour barrier function